The walker scandal culminated in the termination of the Victor II (Project 671RT) at just 7 units it also highlighted to the Soviets that their submarines could be heard at distances beyond weapons range of their own submarines.

Alfa is no exception, on the edge of the rear hydroplanes you will find two outboard electric motors with twin screws these were used as creep motors, how successful they are we don't know but what we do know is nothing mechanical on alfa (like older boats and some newer ones) was rafted which meant noise emanated right through deck and hull then out into the water.

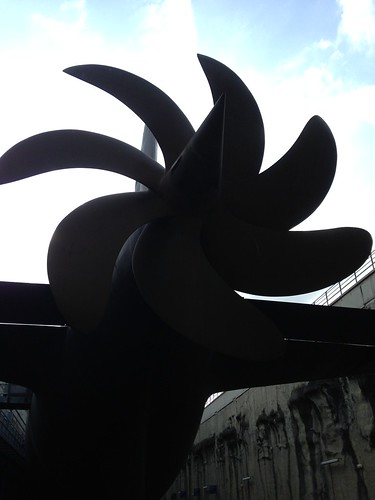

the Problems with a 5 blade screw means that the screw must turn faster to produce more forward propulsion for higher speed which has a down side it also creates low pressure on the tips of the blades which effectively boil the water and creates oxygen bubbles which burst this is what we call cavitation.

If you look at the 705's screw its much smaller than the later boats and western boats an example for size comparison the project 877 6 blade screw is roughly the same size yet the boat is much smaller in dimensions (but heavier due to steel construction)

You then see the adaption of a 7 scew blade propeller

Le Redoubtable S611

Le Redoubtable S611 by

B S, on Flickr

The reason for this is simple the large diameter propeller turns slower but produces as much thrust it also cuts down on the low pressure by turning slower and at higher speed the shape negates the low pressure and dissipates the oxygen bubbles more effectively so you thereby have a submarine that can travel faster quieter with less revolutions of the propeller.

It is also worth noting that the bubbles of oxygen that explode on the propellers surface causes dimples on the blades and cuts & dents on the leading edges which means the propeller isn't as efficient as it should be and as the surface is not smooth it can create more noise.

This can be detected by a good sonar operator !

Counter rotating screws were trialed on the Project 671 RTMK Victor III with limited success notably they were not fitted to the Schuchka Project 971 Akula or later boats.

It appears a new way forward is Pump-jet propulsion basically a slow spinning turbine or screw with multiple blades like a jet front fan which sucks in water forward and ejects water out a smaller channel aft this has been favored by the USA UK and Russia in recent times we do know the Seawolf Virginia Trafalgar Astute Yasen Borei & also a project 877V kilo are fitted with these.

While Russian in terms of computer technology lags a little behind the west they are advanced in other ways SOKS is a real device and has been mounted on many vessels in fact a project 627A November class trailer an american Boomer out of Rota Spain in the 1980's using the system, Russia has also heavily invested in upgrading and replacing sonar systems in older boats.