01-15-20, 01:12 PM

01-15-20, 01:12 PM

|

#3081

|

|

Gefallen Engel U-666

Join Date: Jul 2013

Location: On a tilted, overheated, overpopulated spinning mudball on Collision course with Andromeda Galaxy

Posts: 27,955

Downloads: 22

Uploads: 0

|

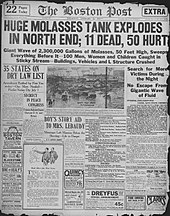

TOO MUCH MOLASSIS; NOT ENOUGH MANGANESE

TOO MUCH MOLASSIS; NOT ENOUGH MANGANESE

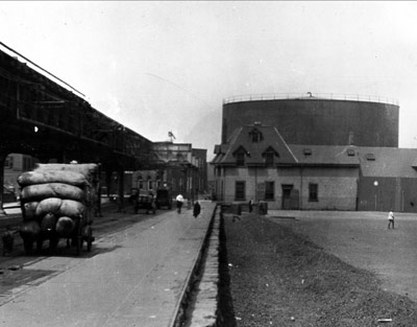

1919: Around lunchtime on the afternoon of January 15, 1919, a giant tank of molasses burst open in Boston’s North End. More than two million gallons of thick liquid poured out like a tsunami wave, reaching speeds of up to 35 miles per hour. The molasses flooded streets, crushed buildings and trapped horses in an event that ultimately killed 21 people and injured 150 more. The smell of molasses lingered for decades. REASONS: Among them: flawed steel, safety oversights, fluctuating air temperatures and the principles of fluid dynamics- ALL CAPPED BY CORPORATE GREED. https://www.history.com/news/great-molasses-flood-science  <CLIK 2 ENLARGE) BEFORE> <CLIK 2 ENLARGE) BEFORE> AFTER> AFTER>

Several factors might have contributed to the disaster. The tank was constructed poorly and tested insufficiently, and carbon dioxide production might have raised the internal pressure due to fermentation in the tank. Warmer weather the previous day would have assisted in building this pressure, as the air temperature rose from 2 to 41 °F (−17 to 5.0 °C) over that period. The failure occurred from a manhole cover near the base of the tank, and a fatigue crack there possibly grew to the point of criticality.

The tank had been filled to capacity only eight times since it was built a few years previously, putting the walls under an intermittent, cyclical load. Several authors say that the Purity Distilling Company was trying to out-race prohibition,as the 18th amendment (CORPORATE GREED!) was ratified the next day (January 16, 1919) and took effect one year later.An inquiry after the disaster revealed that Arthur Jell, USIA's treasurer, neglected basic safety tests while overseeing construction of the tank, such as filling it with water insufficient to check for leaks, and ignored warning signs such as groaning noises each time the tank was filled. He had no architectural or engineering experience. When filled with molasses, the tank leaked so badly that it was painted brown to hide them. Local residents collected leaked molasses for their homes. A 2014 investigation applied modern engineering analysis and found that the steel was half as thick as it should have been for a tank of its size, even with the lax standards of the day, and it also lacked manganese  and was made more brittle as a result.. The tank's rivets were also apparently flawed, and cracks first formed at the rivet holes.

In 2016, a team of scientists and students at Harvard University conducted extensive studies of the disaster, gathering data from many sources, including 1919 newspaper articles, old maps, and weather reports. The student researchers also studied the behavior of cold corn syrup flooding a scale model of the affected neighborhood. The researchers concluded that the reports of the high speed of the flood were credible.Two days before the disaster, warmer molasses had been added to the tank, reducing the viscosity of the fluid. When the tank collapsed, the fluid cooled quickly as it spread, until it reached Boston's winter evening temperatures and the viscosity increased dramatically. The Harvard study concluded that the molasses cooled and thickened quickly as it rushed through the streets, (EST: 35 MPH??!!) hampering efforts to free victims before they suffocated. and was made more brittle as a result.. The tank's rivets were also apparently flawed, and cracks first formed at the rivet holes.

In 2016, a team of scientists and students at Harvard University conducted extensive studies of the disaster, gathering data from many sources, including 1919 newspaper articles, old maps, and weather reports. The student researchers also studied the behavior of cold corn syrup flooding a scale model of the affected neighborhood. The researchers concluded that the reports of the high speed of the flood were credible.Two days before the disaster, warmer molasses had been added to the tank, reducing the viscosity of the fluid. When the tank collapsed, the fluid cooled quickly as it spread, until it reached Boston's winter evening temperatures and the viscosity increased dramatically. The Harvard study concluded that the molasses cooled and thickened quickly as it rushed through the streets, (EST: 35 MPH??!!) hampering efforts to free victims before they suffocated.

__________________

"Only two things are infinite; The Universe and human squirrelyness; and I'm not too sure about the Universe"

|

|

|